Solder for 203H Soldering Station

Price: Contact Us

Product Description

203H soldering station The 203H soldering station is a specialized high-temperature unit commonly used for electronic repair and assembly. It features precise temperature control, fast heating, and compatibility with various soldering tips (such as the T12 series), allowing efficient soldering of SMD components, ICs, and circuit boards. Its compact design and ease of use make it suitable for both professional technicians and trainees.

✓

Technical Specifications

Technical specifications of the 203H soldering station

- Product Name 203H adjustable temperature electronic soldering station

- Product Code: 203H

- Main material: Electrostatic powder-coated metal casing for rust resistance; heat-resistant ABS handle; high-quality alloy heating core.

- Color: Gray – Black

- Machine dimensions: 125 x 95 x 115 mm

- Weight: 2.2 kg (including soldering handle)

- Temperature range: 200°C – 480°C

- Operating voltage: AC 220V / 50Hz

- Power: 60W – 75W

- Display screen: Digital LED

- Power cord length: 1.2m

- Soldering iron handle length: 120mm

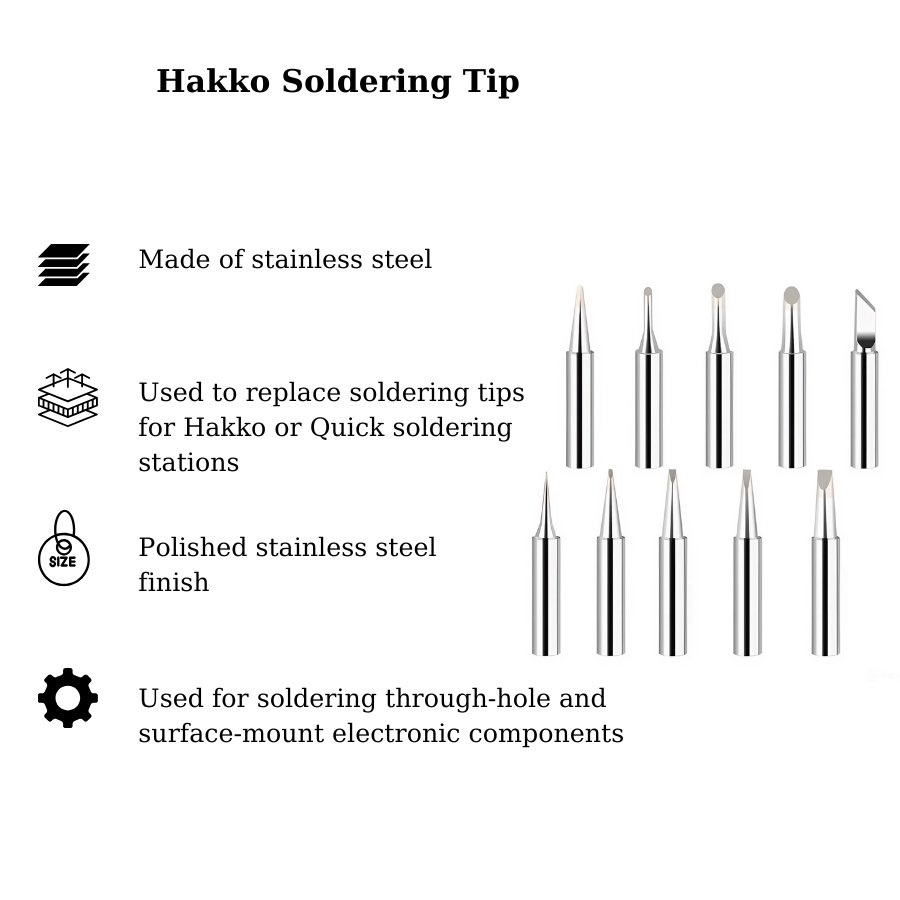

- Compatible soldering tips: Hakko T12, T18, 900M series

Bạn vui lòng nhập đúng số điện thoại để chúng tôi sẽ gọi xác nhận đơn hàng trước khi giao hàng.

Ngoài ra bạn có thể đặt hàng trực tiếp qua các kênh sau:

AN BINH VINA TRADING & SERVICE CO., LTD

Trụ sở: TDP Khả Lý Thượng, P. Quảng Minh, TX Việt Yên, Tỉnh Bắc Giang.

Đà Nẵng: 95 Ngô Quyền, Thọ Quang, Sơn Trà, Đà Nẵng.

Hồ Chí Minh: 8/1A Ấp 1, Xã Bình Mỹ, Huyện Củ Chi, TP HCM.

Review Solder for 203H Soldering Station