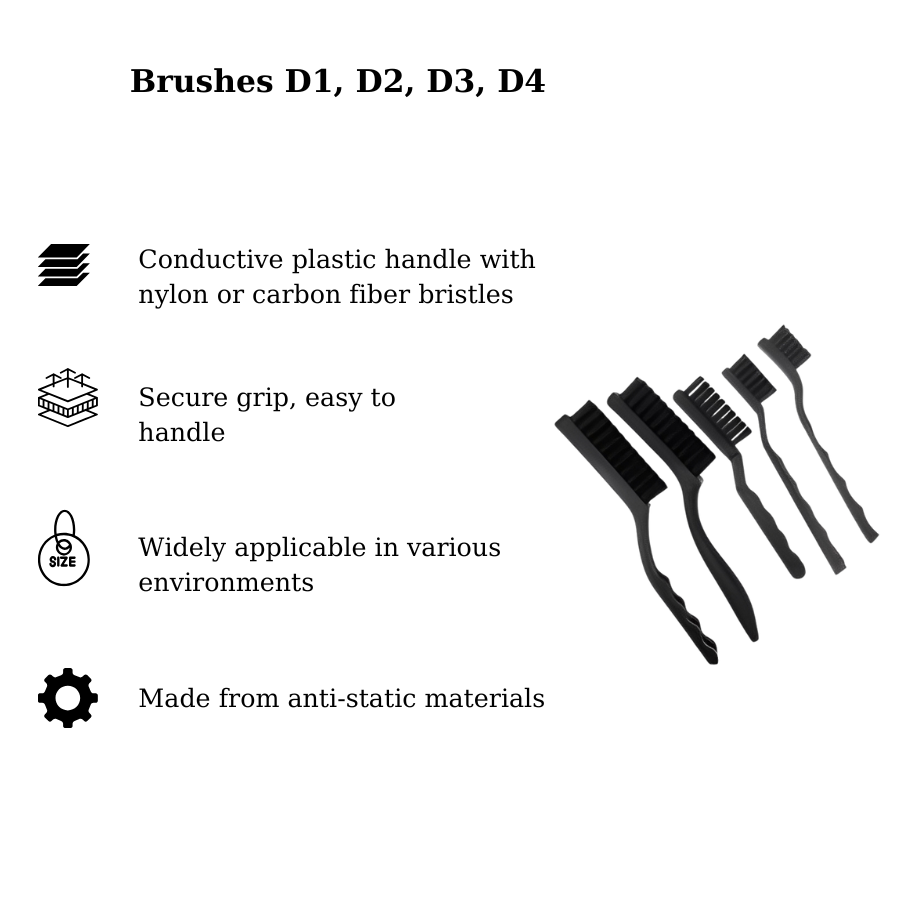

Carbon Fiber ESD-Safe Brush D1, D2, D3, D4

Price: Contact Us

Product Description

Bàn chải D1, D2, D3, D4 là các loại bàn chải chống tĩnh điện chuyên dụng trong vệ sinh linh kiện điện tử. Chúng có cán nhựa dẫn điện và lông nylon hoặc sợi carbon giúp loại bỏ bụi mà không gây phóng tĩnh điện. Mỗi loại có kích thước đầu chải khác nhau: D1 nhỏ, D2 vừa, D3 dài và D4 lớn – phù hợp cho từng vị trí làm sạch từ chi tiết nhỏ đến bề mặt rộng. Thích hợp sử dụng trong phòng sạch, SMT, và nhà máy sản xuất điện tử.

✓

Technical Specifications

Detailed Product Description

Product Name Anti-static Brushes D1, D2, D3, D4

Product Code: Anti-static Brushes D1, D2, D3, D4

Material: Handle made of anti-static ABS plastic, with conductive carbon fiber bristles.

Color: Black

Size:

-

D1: Length 160mm – Brush head width 10mm

-

D2: Length 120mm – Brush head width 6mm

-

D3: Length 180mm – Small angled brush head

-

D4: Length 150mm – Pointed brush head

Weight: Lightweight, ranging from 10 to 25g depending on the model.

With various size and shape options, the D1–D4 brush set meets all small-detail cleaning needs in environments requiring strict ESD control.

Bạn vui lòng nhập đúng số điện thoại để chúng tôi sẽ gọi xác nhận đơn hàng trước khi giao hàng.

Ngoài ra bạn có thể đặt hàng trực tiếp qua các kênh sau:

AN BINH VINA TRADING & SERVICE CO., LTD

Trụ sở: TDP Khả Lý Thượng, P. Quảng Minh, TX Việt Yên, Tỉnh Bắc Giang.

Đà Nẵng: 95 Ngô Quyền, Thọ Quang, Sơn Trà, Đà Nẵng.

Hồ Chí Minh: 8/1A Ấp 1, Xã Bình Mỹ, Huyện Củ Chi, TP HCM.

Review Carbon Fiber ESD-Safe Brush D1, D2, D3, D4