ESD-Safe Cleanroom Splicing Tape

Price: Contact Us

Product Description

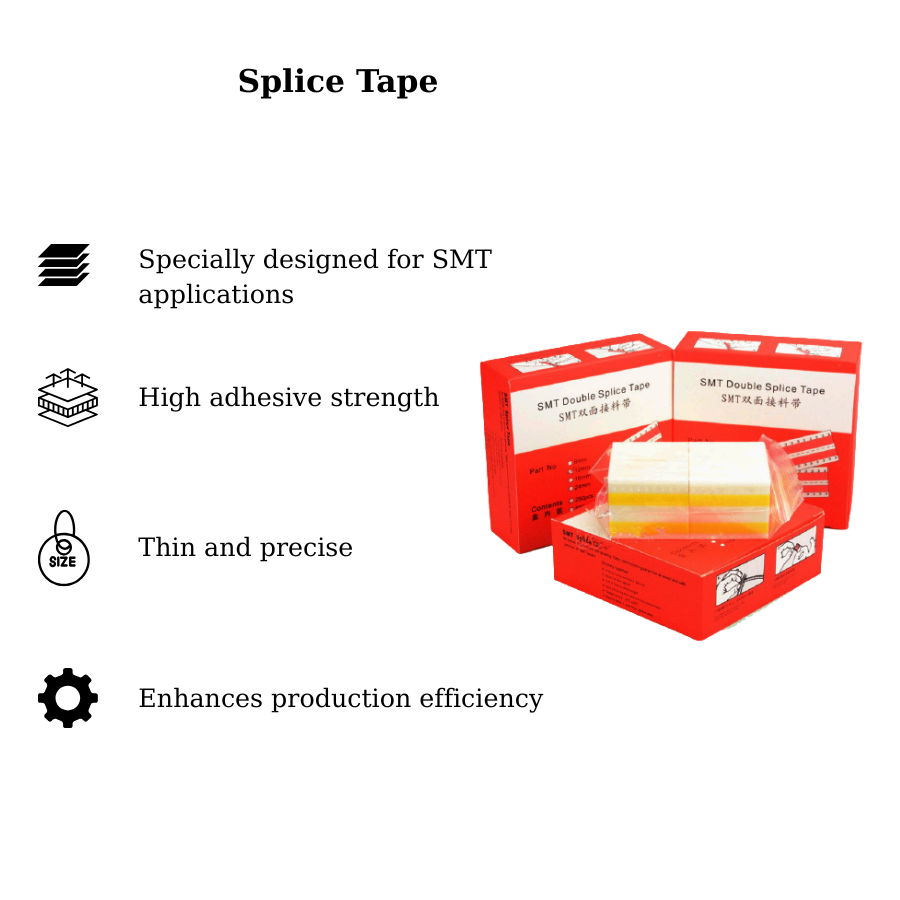

Splicing tape is a specialized adhesive tape used for connecting SMD component reels on SMT pick-and-place machines. The product features high adhesion, thin profile, and precise alignment, ensuring continuous machine operation without interruption. Available in various sizes such as 8mm, 12mm, and 16mm, it is compatible with different types of carrier tapes. This tape helps improve production efficiency and minimize machine downtime in electronic manufacturing processes.

✓

Technical Specifications

Product Description: SMT Splicing Tape

Product Name ESD-Safe Cleanroom Splicing Tape

Product Code: Depending on the size and manufacturer (e.g., SMT-ESD-TAPE-8MM, SMT-ESD-TAPE-12MM).

-

Material: Anti-static PET/PI film with specialized acrylic adhesive.

-

Common Sizes: 8mm, 12mm, 16mm (width) – roll length from 50m to 100m.

-

Color: Transparent, blue, or yellow (depending on type).

-

Weight: Lightweight and convenient for both manual and automatic operations.

The splicing tape adheres strongly to component carrier tapes without leaving adhesive residue, while providing anti-static protection to ensure the safety of sensitive components.

Bạn vui lòng nhập đúng số điện thoại để chúng tôi sẽ gọi xác nhận đơn hàng trước khi giao hàng.

Ngoài ra bạn có thể đặt hàng trực tiếp qua các kênh sau:

AN BINH VINA TRADING & SERVICE CO., LTD

Trụ sở: TDP Khả Lý Thượng, P. Quảng Minh, TX Việt Yên, Tỉnh Bắc Giang.

Đà Nẵng: 95 Ngô Quyền, Thọ Quang, Sơn Trà, Đà Nẵng.

Hồ Chí Minh: 8/1A Ấp 1, Xã Bình Mỹ, Huyện Củ Chi, TP HCM.

Review ESD-Safe Cleanroom Splicing Tape