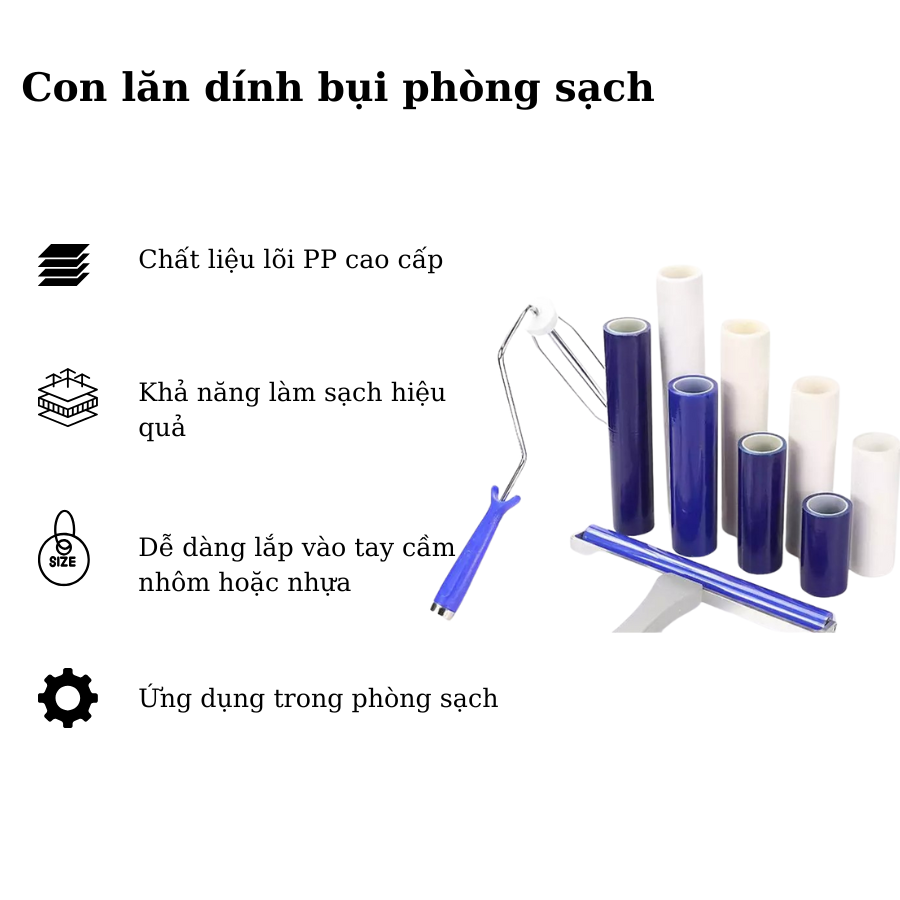

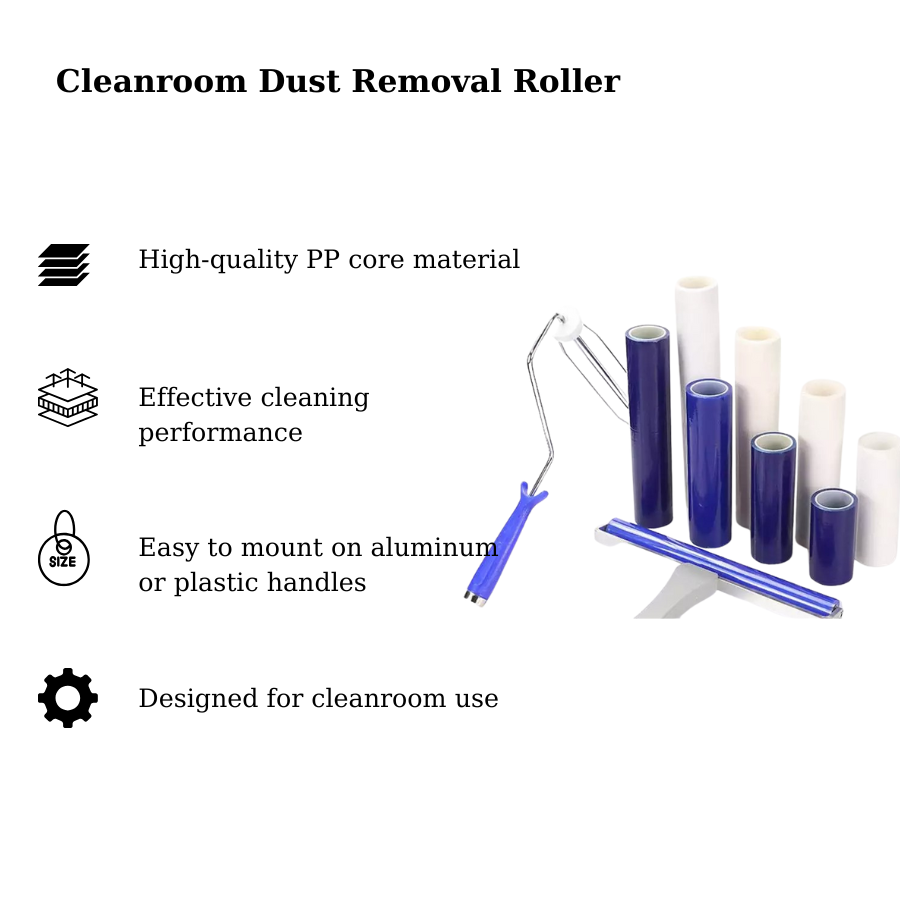

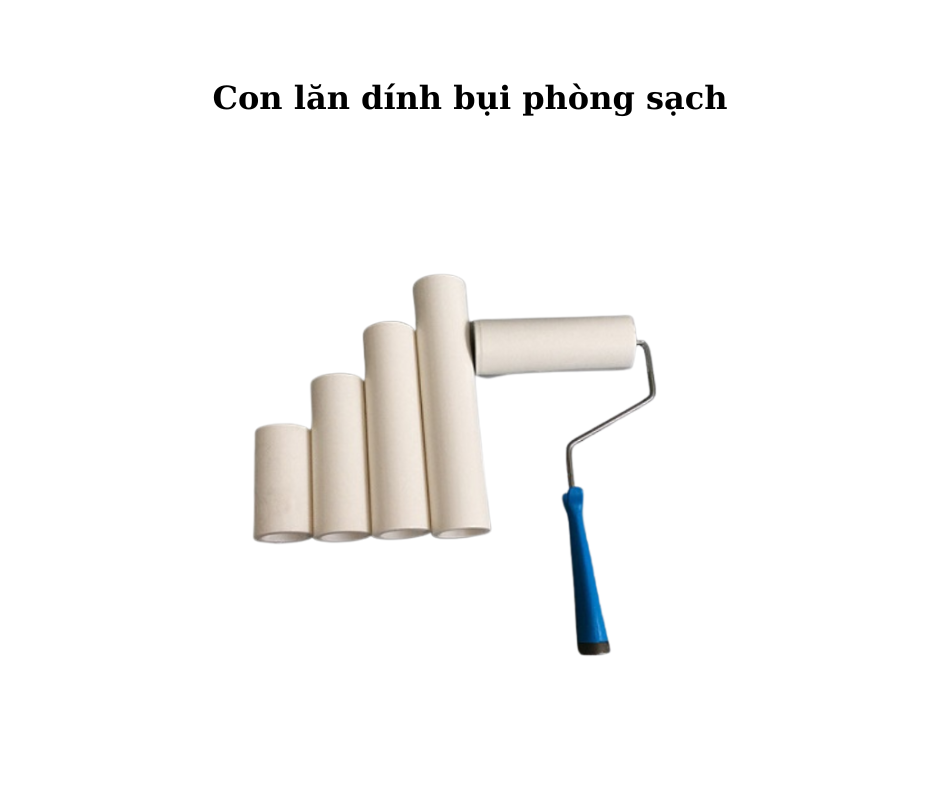

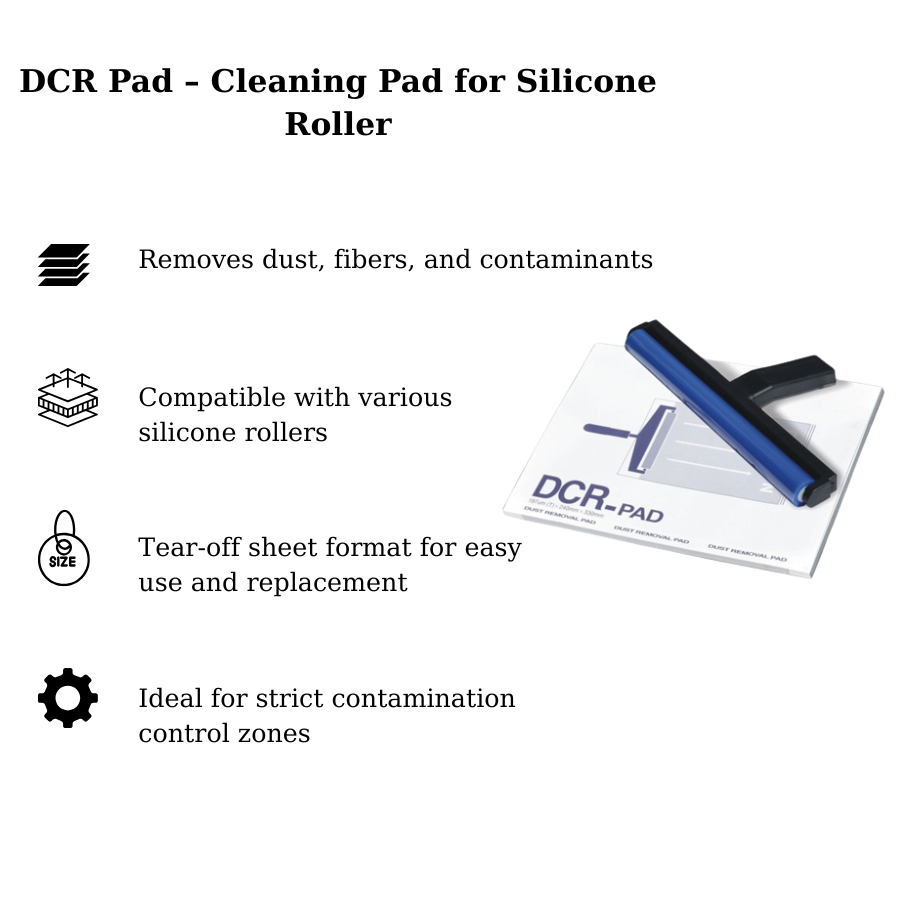

Cleanroom Sticky Roller

Price: Contact Us

Product Description

The cleanroom adhesive roller is designed to remove dust, lint, and small particles from product surfaces or cleanroom floors. The specialized adhesive layer leaves no residue, ensuring an absolutely clean surface. The lightweight roller core is easy to replace and can be conveniently mounted onto the handle. It is suitable for use in environments that require high cleanliness standards such as electronics, semiconductors, and healthcare.

✓

Bạn vui lòng nhập đúng số điện thoại để chúng tôi sẽ gọi xác nhận đơn hàng trước khi giao hàng.

Ngoài ra bạn có thể đặt hàng trực tiếp qua các kênh sau:

AN BINH VINA TRADING & SERVICE CO., LTD

Trụ sở: TDP Khả Lý Thượng, P. Quảng Minh, TX Việt Yên, Tỉnh Bắc Giang.

Đà Nẵng: 95 Ngô Quyền, Thọ Quang, Sơn Trà, Đà Nẵng.

Hồ Chí Minh: 8/1A Ấp 1, Xã Bình Mỹ, Huyện Củ Chi, TP HCM.

Review Cleanroom Sticky Roller