Solder for Hakko Soldering Tips

Price: Contact Us

Product Description

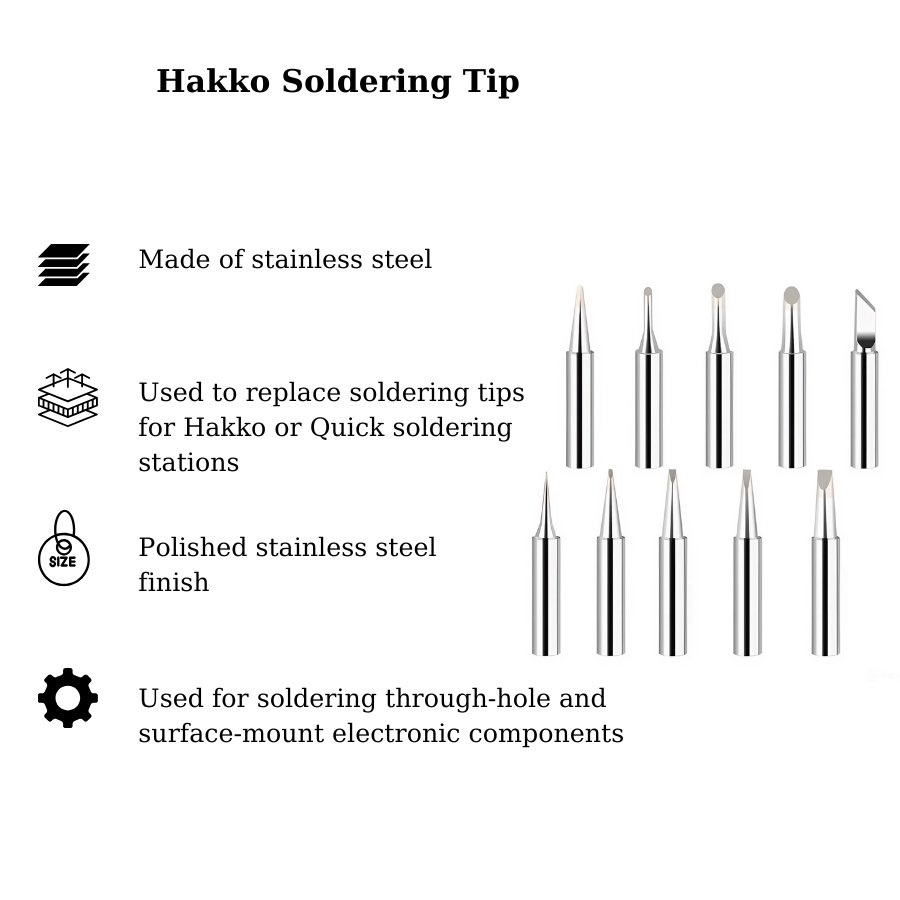

Hakko Soldering Tip It is a specialized soldering tip designed for Hakko electronic soldering stations (Japan). The tip is made of pure copper, plated with iron, and coated with an anti-oxidation layer. The product offers excellent thermal conductivity, long lifespan, rapid heating, and is ideal for high-precision soldering tasks on SMD components and electronic circuit boards.

✓

Technical Specifications

Technical Specifications of Hakko Soldering Tip

-

Popular series T18, T12

-

Tip shape Pointed (T18-B), chisel (T18-C1, T12-BC2), knife (T18-K), ultra-fine pointed (T12-ILS)

-

Tip size 0.2mm – 5.0mm

-

Recommended operating temperature 280°C – 400°C

-

Material: Pure copper coated with anti-corrosion alloy

-

Compatibility Hakko soldering handles 936, 937, FX-888, FX-951, FM-203, etc.

Bạn vui lòng nhập đúng số điện thoại để chúng tôi sẽ gọi xác nhận đơn hàng trước khi giao hàng.

Ngoài ra bạn có thể đặt hàng trực tiếp qua các kênh sau:

AN BINH VINA TRADING & SERVICE CO., LTD

Trụ sở: TDP Khả Lý Thượng, P. Quảng Minh, TX Việt Yên, Tỉnh Bắc Giang.

Đà Nẵng: 95 Ngô Quyền, Thọ Quang, Sơn Trà, Đà Nẵng.

Hồ Chí Minh: 8/1A Ấp 1, Xã Bình Mỹ, Huyện Củ Chi, TP HCM.

Review Solder for Hakko Soldering Tips