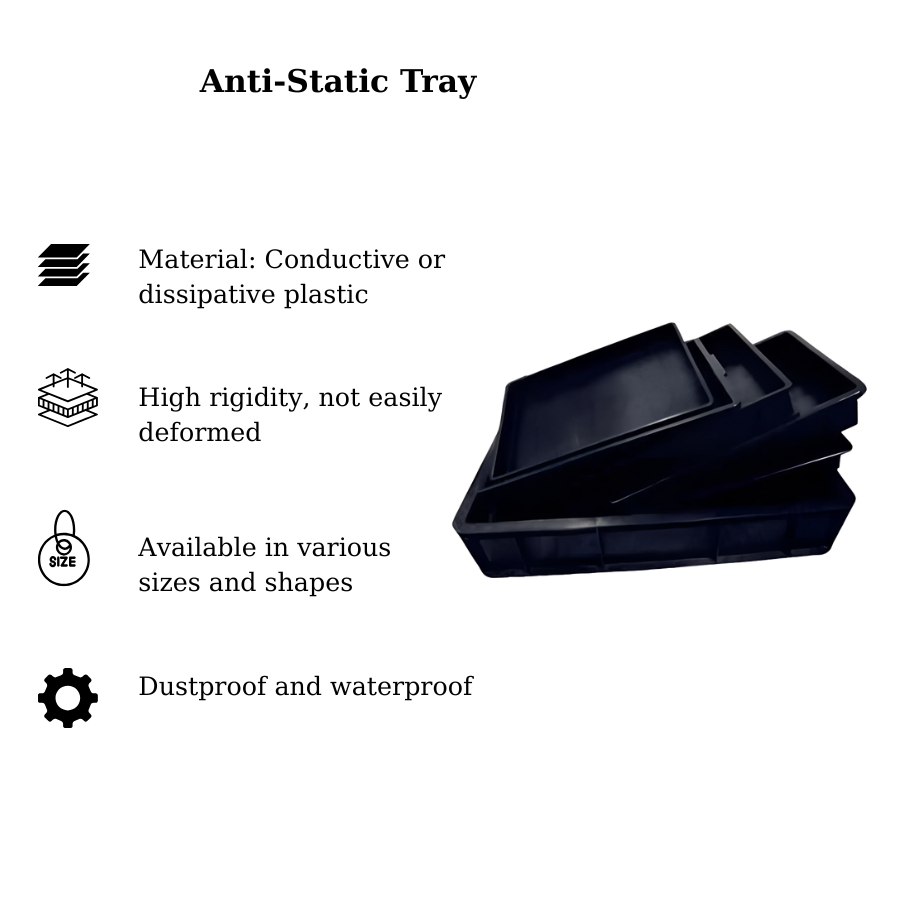

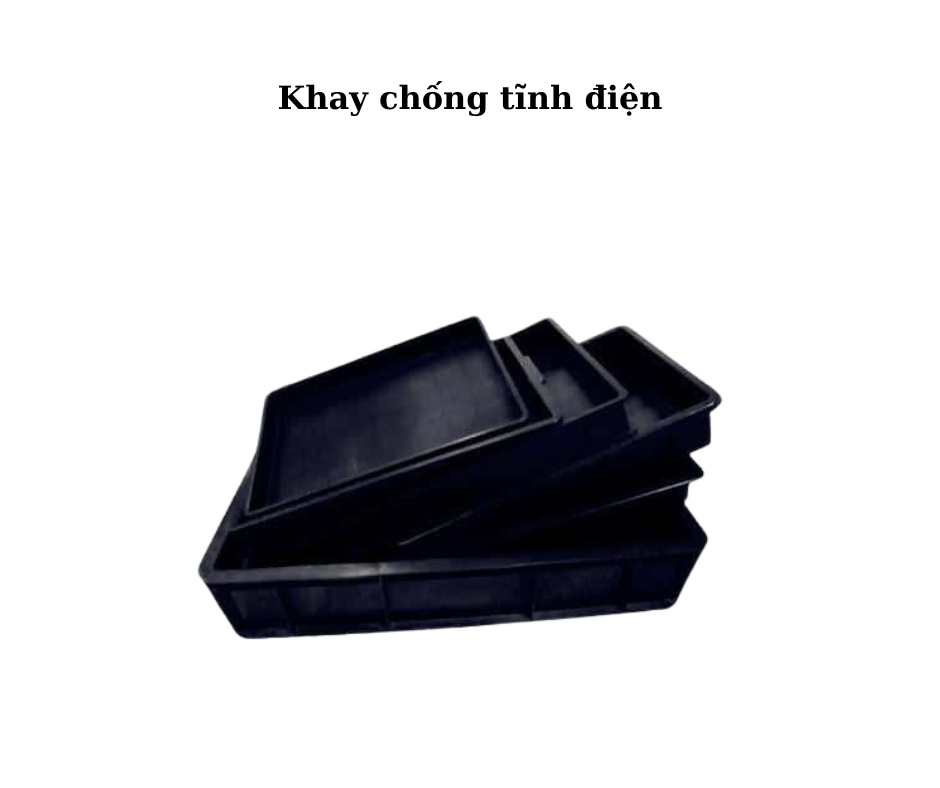

ESD tray Made from conductive plastic, it effectively prevents static charge accumulation and electrostatic discharge (ESD), ensuring the safe protection of electronic components. The product is durable, impact-resistant, easy to clean, and suitable for use in cleanrooms and electronic manufacturing facilities.

ESD Carbon Fiber Filled PC Plastic Anti-Static Tray

Price: Contact Us

Product Description

Đặt mua Khay chống tĩnh điện nhựa PC có pha sợi carbon ESD

ESD Carbon Fiber Filled PC Plastic Anti-Static Tray

Price: Contact Us

Bạn vui lòng nhập đúng số điện thoại để chúng tôi sẽ gọi xác nhận đơn hàng trước khi giao hàng.

Ngoài ra bạn có thể đặt hàng trực tiếp qua các kênh sau:

AN BINH VINA TRADING & SERVICE CO., LTD

Trụ sở: TDP Khả Lý Thượng, P. Quảng Minh, TX Việt Yên, Tỉnh Bắc Giang.

Đà Nẵng: 95 Ngô Quyền, Thọ Quang, Sơn Trà, Đà Nẵng.

Hồ Chí Minh: 8/1A Ấp 1, Xã Bình Mỹ, Huyện Củ Chi, TP HCM.

Review ESD Carbon Fiber Filled PC Plastic Anti-Static Tray