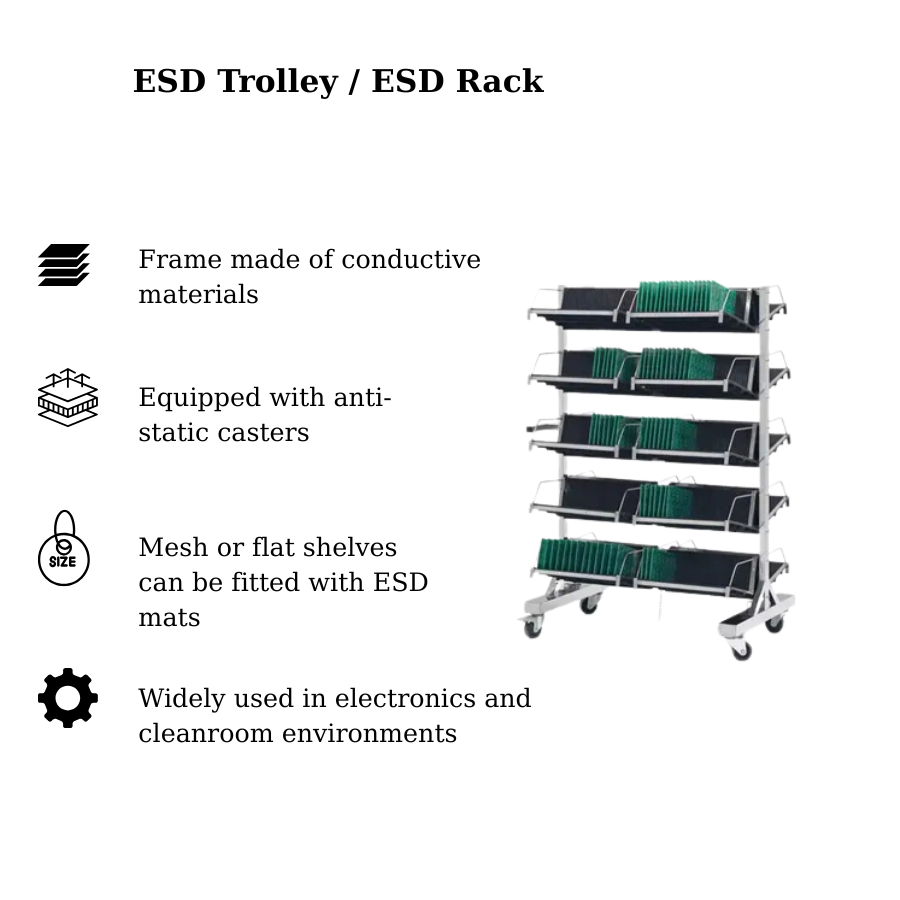

ESD Trolley / ESD Rack

Price: Contact Us

Product Description

The anti-static trolley/rack is made from chrome-plated or powder-coated steel frame, providing effective electrostatic control and charge dissipation. The wheels and joints are conductive, ensuring safety when moving sensitive components. It can be connected to grounding wires to enhance ESD protection. Ideal for use in electronics manufacturing plants, SMT lines, cleanrooms, and component assembly areas.

✓

Technical Specifications

Product Description – Anti-static Trolley and Rack

-

Product Name Anti-static Trolley / Anti-static Rack

-

Product Code: (Depending on the model)

-

Main material: Made from SUS 304 stainless steel, anodized aluminum profiles, ESD-coated powder-painted steel, ESD PVC, or anti-static laminate boards.

-

Size: Customizable upon request (common sizes: 900×600×1500 mm or 1200×600×1800 mm).

-

Color: Stainless steel silver, ESD gray, ESD black, or customized upon request.

-

Load capacity: 100 – 500 kg depending on the model.

-

Caster wheels: ESD-safe PU caster wheels, 360° swivel, equipped with safety locking brakes.

The product is precisely engineered with an anti-static surface that meets ESD standards, ensuring maximum safety when storing or transporting goods and components in environments with stringent electrostatic control requirements.

Bạn vui lòng nhập đúng số điện thoại để chúng tôi sẽ gọi xác nhận đơn hàng trước khi giao hàng.

Ngoài ra bạn có thể đặt hàng trực tiếp qua các kênh sau:

AN BINH VINA TRADING & SERVICE CO., LTD

Trụ sở: TDP Khả Lý Thượng, P. Quảng Minh, TX Việt Yên, Tỉnh Bắc Giang.

Đà Nẵng: 95 Ngô Quyền, Thọ Quang, Sơn Trà, Đà Nẵng.

Hồ Chí Minh: 8/1A Ấp 1, Xã Bình Mỹ, Huyện Củ Chi, TP HCM.

Review ESD Trolley / ESD Rack