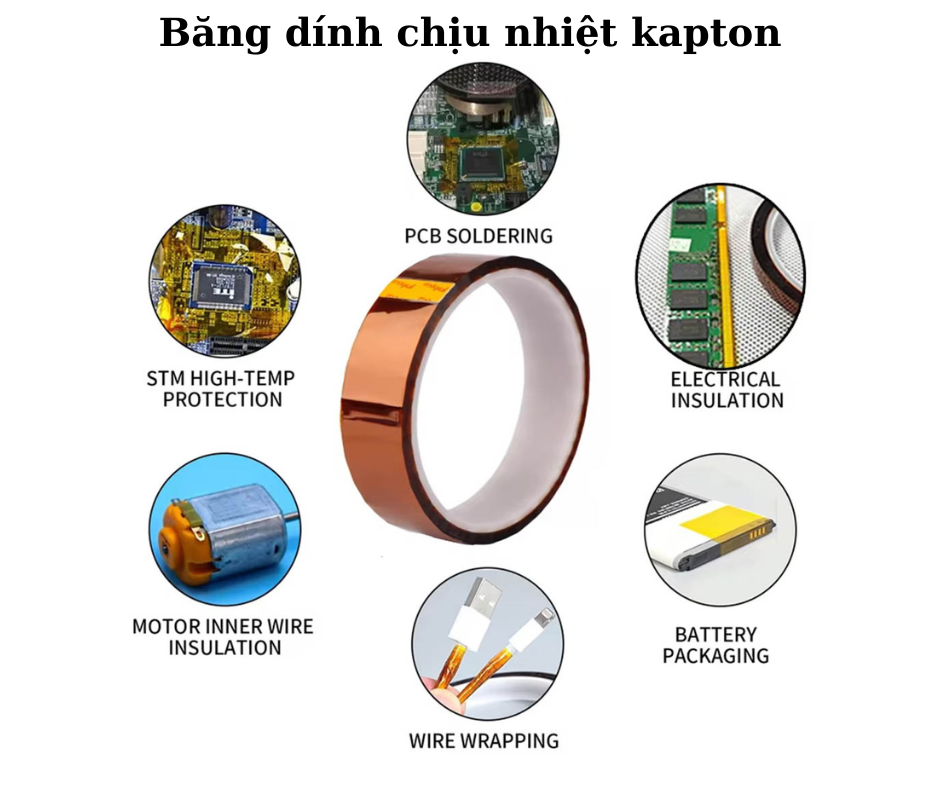

Kapton Heat-Resistant Tape

Price: Contact Us

Product Description

Kapton heat-resistant tape is a specialized material used in the electrical, electronics, 3D printing, and PCB soldering industries, with high-temperature resistance up to 260°C. The product offers excellent adhesion, effective electrical insulation, and leaves no residue after removal, providing optimal surface protection in harsh thermal environments. Learn more about its applications, usage, and where to buy genuine Kapton tape in the detailed article below.

✓

Technical Specifications

Basic technical specifications

| Attributes: | Typical Values |

|---|---|

| Base material | Polyimide (Kapton) |

| Adhesive Layer | Heat-resistant silicone |

| Film thickness | 25 µm (1 mil), also available in 50 µm, 75 µm, etc. |

| Total thickness | Approximately 60 µm – 80 µm (including adhesive layer) |

| Width | From 5 mm to 500 mm (customizable) |

| Roll Length | Usually 33 m, 50 m, or customized upon request. |

| Operating Temperature | -73°C to +280°C (up to 300°C for short periods) |

| Insulation resistance | >10⁶ MΩ |

| Tensile strength | ≥ 150 N/25mm |

| Adhesion strength | ~6 – 7 N/25 mm (depending on type) |

| Flame Retardant | UL-94 V-0 (excellent flame retardancy) |

Bạn vui lòng nhập đúng số điện thoại để chúng tôi sẽ gọi xác nhận đơn hàng trước khi giao hàng.

Ngoài ra bạn có thể đặt hàng trực tiếp qua các kênh sau:

AN BINH VINA TRADING & SERVICE CO., LTD

Trụ sở: TDP Khả Lý Thượng, P. Quảng Minh, TX Việt Yên, Tỉnh Bắc Giang.

Đà Nẵng: 95 Ngô Quyền, Thọ Quang, Sơn Trà, Đà Nẵng.

Hồ Chí Minh: 8/1A Ấp 1, Xã Bình Mỹ, Huyện Củ Chi, TP HCM.

Review Kapton Heat-Resistant Tape